From motion control systems to robot joints and sensor housings, Bergek supports every stage of innovation, providing customized, high-precision components for the robotics and automation industries.

Precision That Powers Automation

Flexible Production

Support for both small-batch customization and large-scale production with short lead times.

Trusted by Global

Clients

A growing portfolio of aviation clients worldwide proves our reliability and results.

Complete Inspection

Thorough quality control ensures every part meets aviation-grade standards before delivery.

Supports aerospace-grade materials like titanium and aluminum for high durability.

Broad Material

Compatibility

High Precision CNC

Advanced multi-axis machines meet tight tolerances required in aviation applications.

Fast Prototyping

Quick turnaround for prototype validation, helping clients speed up development cycles.

Why Robotics & Automation Clients Trust Bergek

Strict quality systems ensure compliance with international aerospace standards for safety and reliability.

Certified Quality

We use materials such as aluminum and titanium, tailored to your industry's needs.

Expertise In Materials For Different Industries

Robotics & Automation Manufacturing Solutions With Bergek

In robotics and automation, precision, repeatability, and material integrity are critical. Bergek specializes in producing components that enable reliable motion, accurate sensing, and seamless integration into automated systems. From functional prototypes to full-scale production, we deliver both standard and custom parts with high dimensional accuracy.

Robotics & Automation Manufacturing Possibilities

High Precision Motion Parts

CNC machining enables extremely accurate production of components like joints, shafts, and actuators, critical to robotic stability and performance.

Modular Integration

Custom parts can be engineered for seamless integration into modular and scalable automation systems, enhancing adaptability and flexibility.

Consistent Repeatability

Our manufacturing processes ensure dimensional consistency across batches, which is essential for high-volume automation systems with minimal tolerance for variation.

Lightweight Yet Durable Structures

Using optimized designs and materials, Bergek produces parts that reduce weight without sacrificing strength—ideal for robotic mobility and energy efficiency.

Timing Pulleys

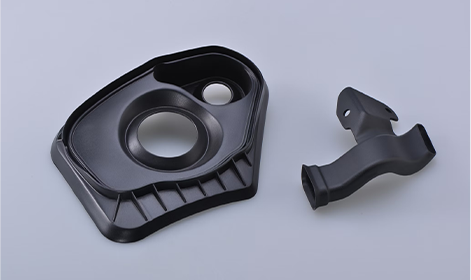

What Kind Of Robotics & Automation Parts Can We Manufacture?

Drive Shafts

Linear Actuator Brackets

CNC Machined Gear Wheels

Coupling Hubs

Bearing Housings

Cam Followers And Sliders

Worm Gear Casings

Machine Base Frames

Hmi Panel Bezels

Robot Arm Support Structures

Sheet Metal Enclosures

Control Box Housings

Safety Covers And Guards

Mounting Plates For Sensors / Motors

Cable Routing Brackets

Aluminum Profiles With CNC Holes

Button & Switch Housings

Touchscreen Display Holders

Emergency Stop Button Covers

LED Indicator Light Panels

Servo Motor Casing Parts

Plastic Gears And Racks

Connector Holders And Sensor Mounts

Laser cutting, bending, stamping, spinning, punching, welding.

Sheet Metal Fabrication

For parts from 1,000 to 50,000 pcs in stainless & soft metal. Evaluate MIM suitability with DFM & material guidance.

Metal Injection Molding

CNC Manufacturing Workflow For Robotics & Automation Parts

We offer low-volume prototype moldings and mass production moldings.

Injection Molding

By using CNC milling & turning, we can make a wide range of prototypes and production parts.

CNC Machining

At Bergek, we aim to become a trusted partner in the future of robotics and intelligent automation. By delivering precision-engineered components with outstanding reliability and flexibility, we empower innovators to transform industries—from smart manufacturing to next-generation service robotics.

Our Vision in Robotics & Automation