Material Characteristics:

Stainless steel: The tendency to work harden is significant and the tool is prone to wear (such as 304 stainless steel is required to use coated tools when cutting).

Cast iron: It is highly brittle and easily produces chips during cutting. Pay attention to the rigidity and chip removal efficiency of the machine tool.

Ferrous metal:

The "backbone" of industrial manufacturing

Material Characteristics:

Aluminum/aluminum alloy: low density (≈2.7g/cm³), good thermal conductivity, suitable for lightweight aerospace.

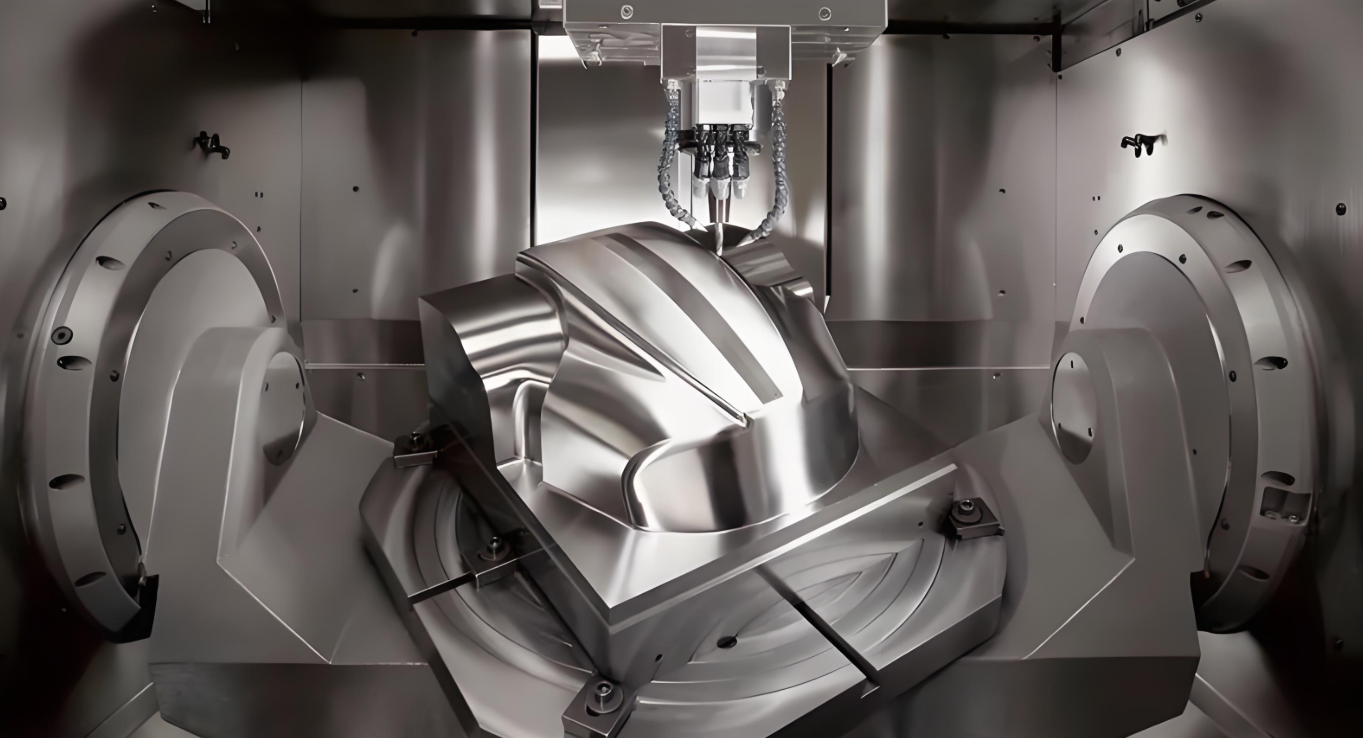

Titanium alloy: high specific strength, high temperature resistance (up to 600℃), used in aircraft engine components.

Nonferrous metals:

"Pioneer" of lightweight and high performance

Material characteristics:

High temperature alloy: It maintains high strength above 650℃ and is used in aircraft engine turbine blades.

Composite materials: Combining metal and ceramic/fiber, with high stiffness and wear resistance (such as Al-SiC composites).

Special Metals:

High temperature alloys (nickel-based, cobalt-based), metal-based composite materials (MMC)

Equipment & Tools Library

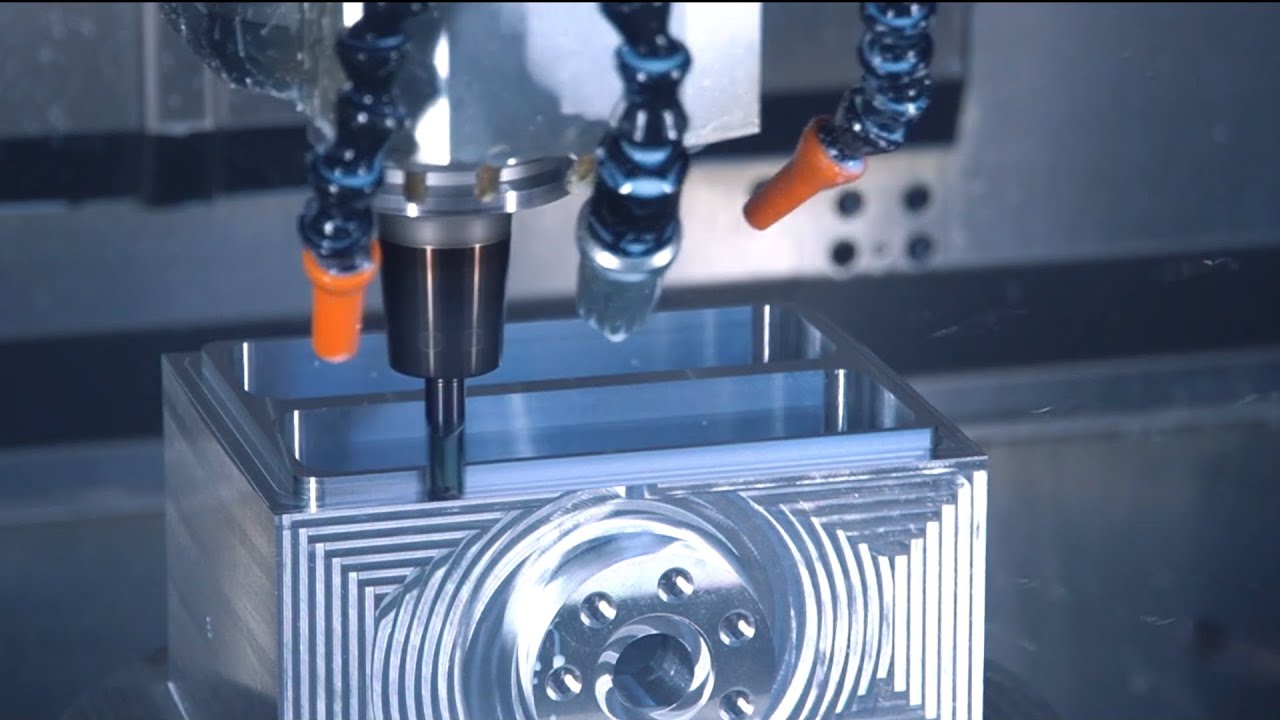

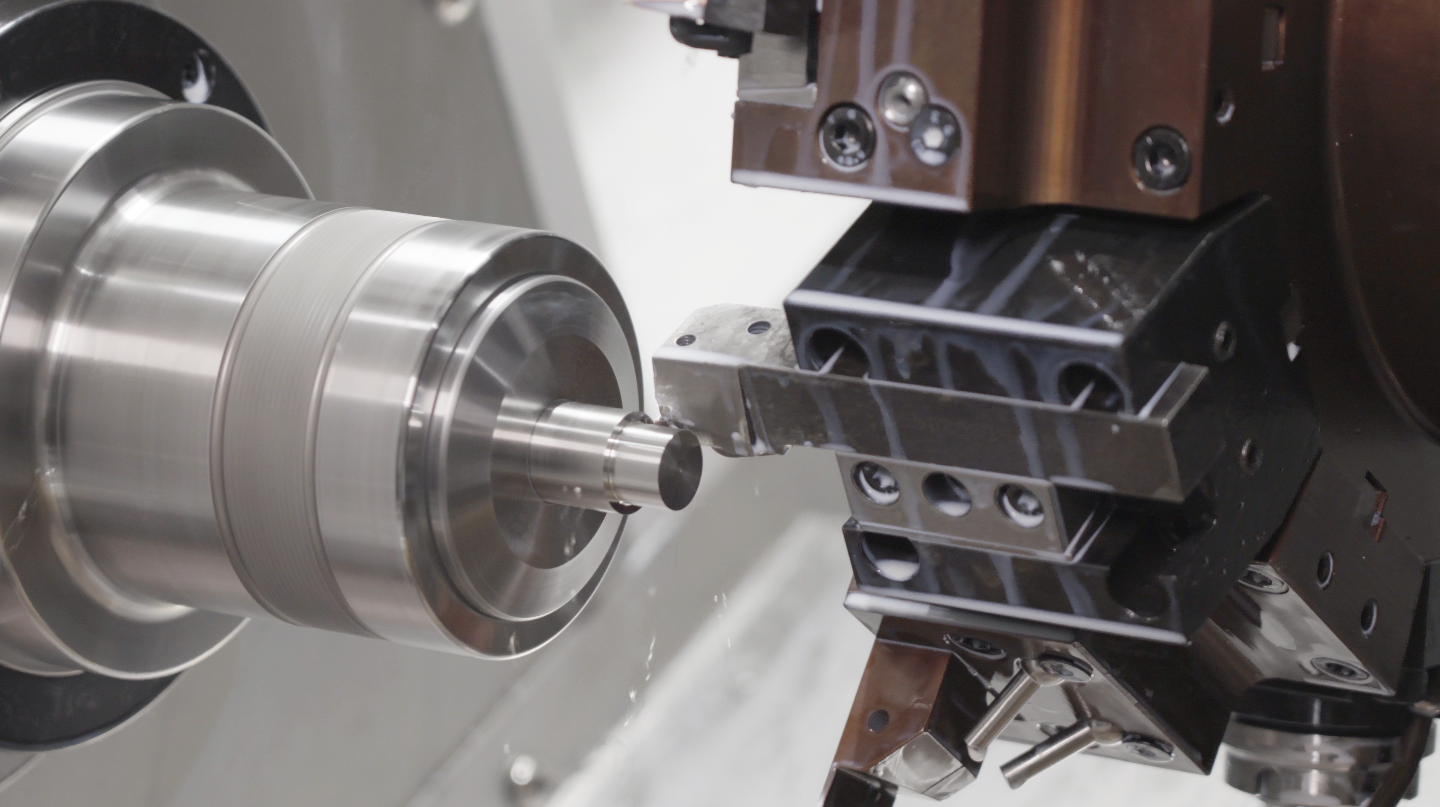

Cutting equipment: machining center, CNC lathe, grinder, drilling machine.

Forming equipment: press, bending machine, plate rolling machine, forging hydraulic press.

Welding equipment: argon arc welding machine, laser welding machine, resistance welding machine.

Detection equipment: three-coordinate measuring instrument, spectrum analyzer, non-destructive testing equipment.

Auxiliary tools: tools (carbide cutting tools, ceramic cutting tools), fixtures, abrasives.