Bergek delivers high-performance, tight-tolerance components tailored for the aerospace industry. Our materials expertise and certified quality systems ensure reliability for critical flight and defense applications.

Precision Manufacturing For Aerospace Excellence

High Precision CNC

Advanced multi-axis machines meet tight tolerances required in aviation applications.

Why Aerospace Clients Trust Bergek

Certified Quality

Strict quality systems ensure compliance with international aerospace standards for safety and reliability.

Fast Prototyping

Quick turnaround for prototype validation, helping clients speed up development cycles.

Flexible Production

Support for both small-batch customization and large-scale production with short lead times.

Broad Material

Compatibility

Supports aerospace-grade materials like titanium and aluminum for high durability.

Complete Inspection

Thorough quality control ensures every part meets aviation-grade standards before delivery.

Trusted by Global

Clients

A growing portfolio of aviation clients worldwide proves our reliability and results.

Expertise In Materials For Different Industries

We use materials such as aluminum and titanium, tailored to your industry's needs.

Aerospace Manufacturing Solutions With Bergek

Precision, reliability, and strict compliance are essential in aerospace part production. With years of experience, Bergek delivers both simple and complex components that meet rigorous industry standards. From prototypes to full production runs, we conduct thorough inspections and quality checks to ensure every part meets aerospace-grade requirements. Contact us to learn how we can support your next aerospace project.

Aerospace parts demand exceptional dimensional accuracy. CNC technology ensures tolerances as tight as ±0.01 mm, critical for components like turbine blades, housings, and fasteners that operate under extreme conditions.

Material Versatility

Aerospace requires high-performance materials like titanium, Inconel, and aluminum alloys. CNC machines can process these hard-to-machine metals efficiently, ensuring both machinability and performance durability.

Repeatability & Certification

CNC machining guarantees high consistency from prototype to production. Combined with quality inspection systems, it supports traceability, compliance, and certification standards such as AS9100 for aerospace.

Aerospace Manufacturing Possibilities

Weight Reduction

CNC machining allows for the precise removal of excess material while maintaining structural integrity. This enables aerospace components to be both lightweight and durable, meeting strict performance and fuel efficiency standards.

Tight Tolerances

Airframe Reinforcement Beams

Drone Propeller Hubs

Ground Support Equipment Shells

Cockpit Control Panels

Fuel Tank Frames

Communication Device Casings

Battery Enclosures

Cabin Pressure Regulators

Satellite Antenna Mounts

Sensor Mount Bases

Landing Gear Housings

Oxygen Supply Modules

Engine Test Stand Fixtures

Maintenance Tool Components

Turbine Blades

What Kind Of Aerospace Parts Can We Manufacture?

Structural Components

Titanium Parts

Instrument Housings

Mounting Brackets & Fixtures

Avionics Panels

Heat Sinks & Thermal Plates

Satellite Components

Custom Fasteners & Bushings

Wing Flap Actuators

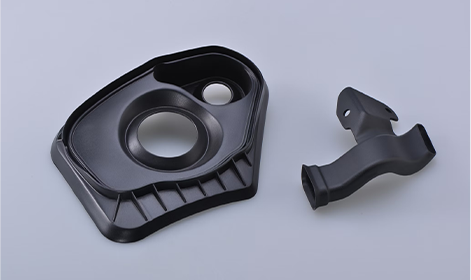

We offer low-volume prototype moldings and mass production moldings.

Injection Molding

Laser cutting, bending, stamping, spinning, punching, welding.

Sheet Metal Fabrication

For parts from 1,000 to 50,000 pcs in stainless & soft metal. Evaluate MIM suitability with DFM & material guidance.

Metal Injection Molding

CNC Manufacturing Workflow For Aerospace Parts

By using CNC milling & turning, we can make a wide range of prototypes and production parts.

CNC Machining

Sheet Metal Fabrication

Laser cutting, bending, stamping, spinning, punching, welding.

We offer low-volume prototype moldings and mass production moldings.

Injection Molding

For parts from 1,000 to 50,000 pcs in stainless & soft metal. Evaluate MIM suitability with DFM & material guidance.

Metal Injection Molding

CNC Manufacturing Workflow For Aerospace Parts

CNC Machining

By using CNC milling & turning, we can make a wide range of prototypes and production parts.

Our Vision In Aerospace

At Bergek, we aim to become a trusted partner in global aerospace innovation. By delivering mission-critical components with unmatched precision and agility, we support clients in pushing the boundaries of flight — from commercial aircraft to next-gen aerospace technologies.