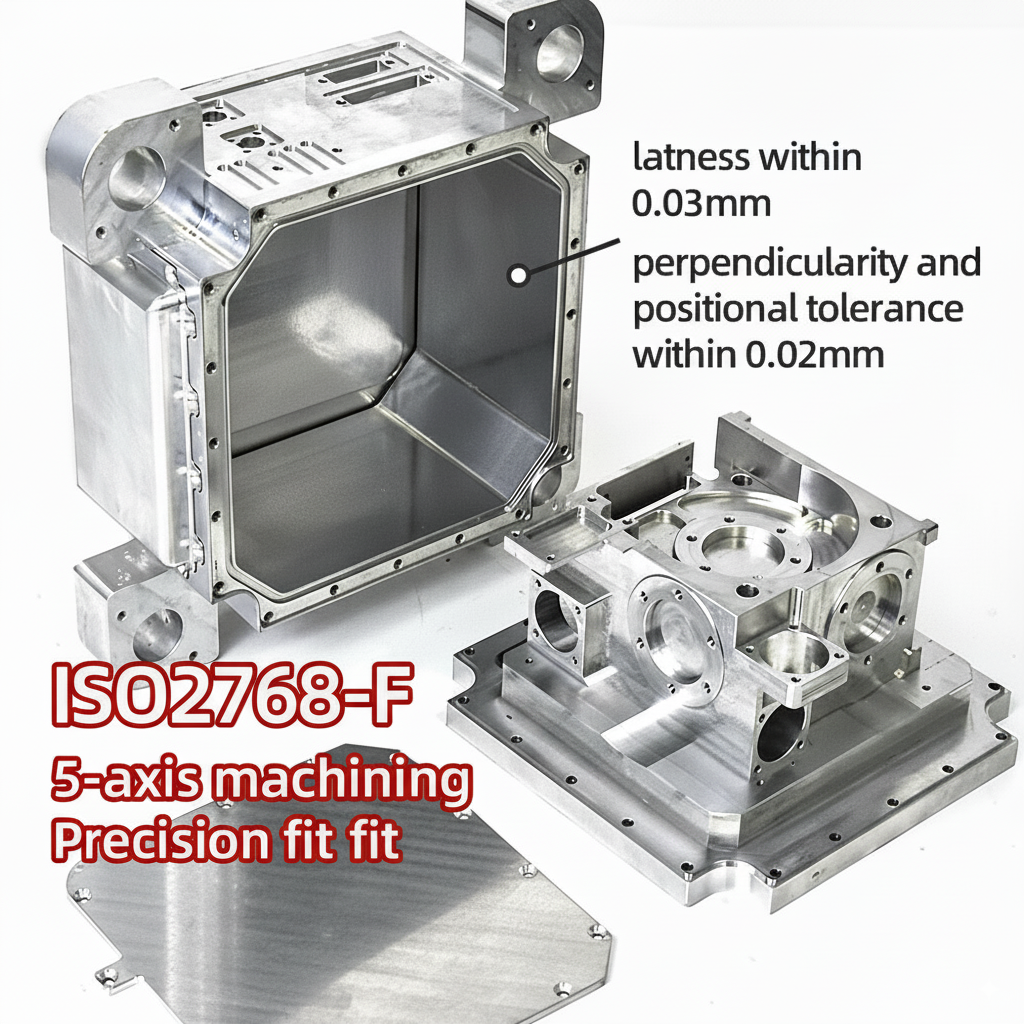

Precision 5-Axis CNC Machining Manufacturer

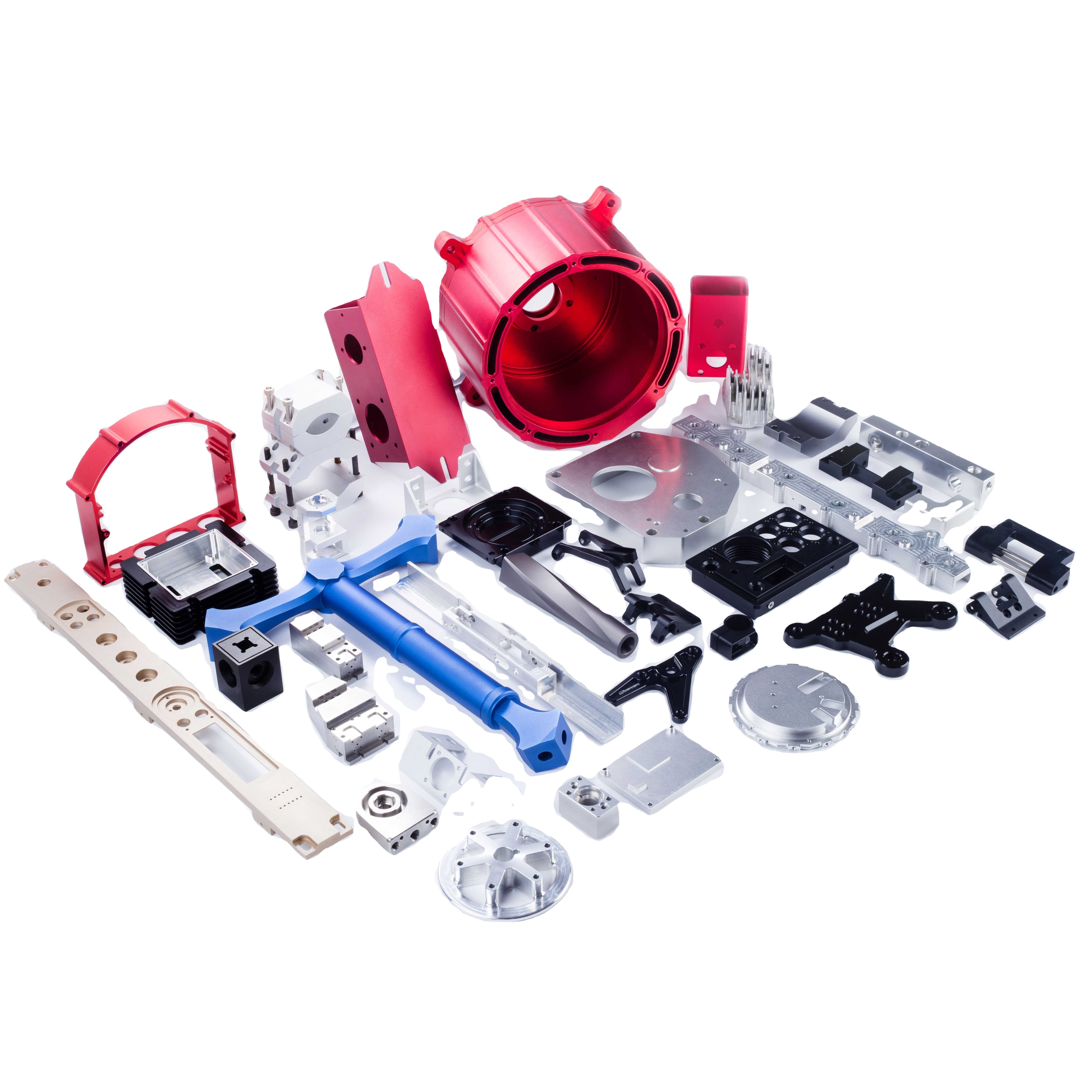

We specialize in high-tolerance 5-axis CNC machined components made from premium-grade aluminum, tailored for aerospace, robotics, and high-performance applications.

Machining Type: 5-Axis CNC Machining

Material: Aerospace-grade Aluminum Alloy

Tolerance: ISO2768-F

Flatness: Within 0.03mm

Perpendicularity: Within 0.02mm

Positional Tolerance: Within 0.02mm

Surface Finish: Ra ≤ 1.6μm

Machining Method: Simultaneous 5-axis milling

Software Compatibility: CAD/CAM

Design File Format: STEP, IGES, STL

Machining Capability: Multi-face complex geometries

Wall Thickness: As low as 0.5mm

Part Size Range: 10mm–500mm

Fixture Type: Custom soft jaws

Deburring: Manual and ultrasonic

Inspection Method: CMM & 3D scanning

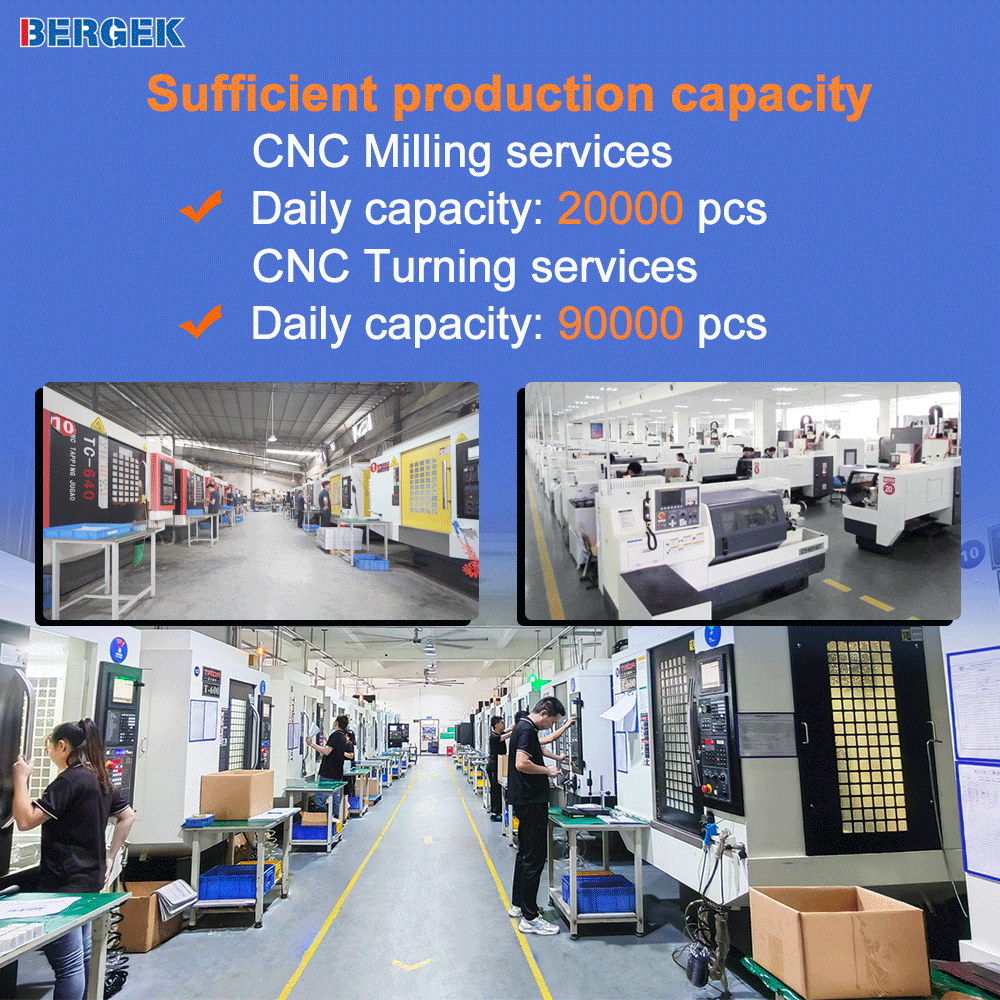

Production Volume: Prototype to medium batch

Applications: Aerospace, Robotics, Defense, Optical Equipment

Turnaround Time: 7–12 working days

Quality Standard: ISO9001 & ISO2768-F

Packaging: Vacuum sealed with anti-static foam

Lead Time: Negotiable based on complexity

Edge Break: 0.2mm chamfer standard

CAD Optimization Support: Yes

OEM/ODM Services: Available

MOQ: 1 Piece

Rust Protection: Anodizing available

Machining Accuracy: ±0.01mm

Thermal Stability: High thermal conductivity materials

Dynamic Balancing: Optional

Thread Machining: UNC/UNF/M/J Metric

Secondary Processes: Anodizing, Powder Coating

Production Equipment: DMG Mori, Haas UMC-750

Certifications: ISO9001, RoHS

Customer Industries: Aerospace, Automotive, Medical, Electronics

3D Model Review: Free before quotation

International Shipping: DHL, FedEx, UPS

Surface Treatment: Customizable per requirement

Toolpath Simulation: Yes

Fixture Design: Provided on request

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

Custom CNC Milling & 5 Axis CNC Machining Services – Precision Aluminum Parts ISO 2768-M&K

Professional CNC milling and 5 axis CNC machining services for precision aluminum parts, following ISO 2768-M&K standards, with high accuracy, multiple finishes, and full OEM/ODM customization.¥0.00¥0.00 -

High Precision 5-Axis CNC Machining Parts Multi-Material Custom Components

This product includes high-precision 5-axis CNC machined parts made from aluminum, stainless steel, copper, brass, titanium, and engineering plastics. Widely used in automotive, aerospace, electronics, medical, and robotics industries. We provide drawing or sample-based customization, fast prototyping, strict quality control, and global delivery.¥0.00¥0.00 -

ISO 9001 Certified 5-Axis CNC Machining Manufacturer High Precision Custom Parts

We are an ISO 9001 certified manufacturer specializing in high precision 5-axis CNC machining. We provide custom CNC components in aluminum, stainless steel, brass, copper, and engineering plastics. Our products are widely used in automotive, aerospace, electronics, robotics, and industrial applications. OEM/ODM supported, fast delivery, strict quality control.¥0.00¥0.00 -

Our 3/4/5 axis CNC machining and milling services offer advanced manufacturing solutions for complex aluminium anodized components, precision parts, and custom speaker housings. We utilize state-of-the-art equipment to ensure high accuracy, tight tolerances, and superior surface finishes. Our services cover a wide range of industries, including electronics, automotive, and aerospace. Whether you need rapid prototyping or full-scale production, our team delivers reliable and cost-effective machining solutions tailored to your requirements.

¥0.00¥0.00