OEM Customized CNC Machined Aluminum & Stainless Steel Parts

Our CNC machining service offers precision aluminum and stainless steel parts, with high-quality surface treatments including mirror polishing and anodizing. These components are designed for high-end applications across multiple industries.

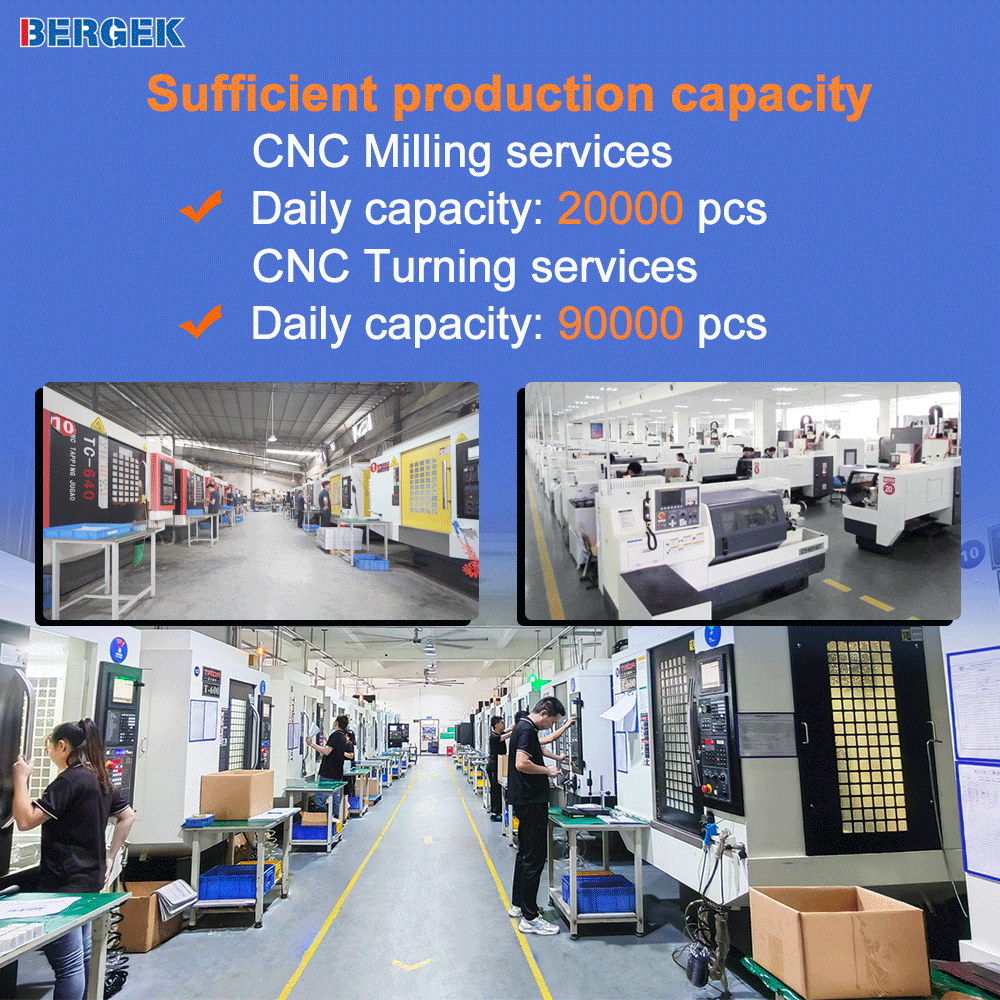

Machining Type: CNC Milling, CNC Turning, 5-Axis

Materials: 6061/7075 Aluminum, 304/316 Stainless Steel

Surface Finishes: Mirror Polishing, Anodizing (Orange, Silver), Brushed

Tolerance: ±0.005mm

Feature Details: Honeycomb decorative panels, deep bores, sharp edges

Color Range: Natural, Silver, Orange

Mechanical Fit: Threaded, press-fit, precision sliding fit

Surface Quality: Optical-grade polishing

Rust Resistance: Stainless steel and anodized aluminum

Weight Optimization: Hollowed and pocketed designs

Applications: Robotics, Optical Systems, Custom Brackets, Automation Components

Wall Thickness: ≥ 0.4mm

Part Size: 5mm to 250mm

Thread Specs: Metric, UNC, UNF

CAD File Support: STEP, IGES, STL, DWG

Post Processing: Sandblasting, Deburring, Laser Marking

Coating Options: Anodized, Electropolished, Passivated

Batch Volume: From prototype to 500 pcs

Sample Availability: Provided upon request

Quality Certification: ISO9001:2015, SGS

Inspection Method: CMM, Height Gauge, Profile Projector

Machinery Used: DMG MORI, HAAS, FANUC, Tsugami

Design Optimization: DFM advice included

Lead Time: 5–10 working days

Packaging: Anti-static foam, sealed bags

OEM/ODM Services: Available

Electromechanical Integration: Supported

Toolpath Strategy: High-efficiency adaptive

Repeat Tolerance: ±0.002mm (batch repeatability)

Fixture Type: Precision holding jigs

Polishing Level: Mirror or satin

Color Customization: Pantone matched anodizing

Shipping: Express by DHL, FedEx, UPS

MOQ: 5 units

Environmental Compliance: RoHS, REACH

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

Customized 5-Axis CNC Machining Services | Precision Metal Components Manufacturer

We provide customized 5-axis CNC machining services for high precision metal parts, including aluminum, stainless steel, brass, copper, and titanium. Our products feature anodized, polished, and plated finishes, and are used in electronics, automotive, robotics, and more. ISO 9001 certified, OEM/ODM, fast prototyping, and global delivery.¥0.00¥0.00 -

Custom 5-Axis CNC Machined Aluminum Parts (6061/7075/2024/5052/6082) - Color Anodized Components

These are custom 5-axis CNC machined aluminum parts made from high-quality alloys such as 6061, 7075, 2024, 5052, and 6082. Featuring color anodized and brushed finishes, our parts are widely used in electronic equipment, automotive, robotics, and more. We support OEM & ODM, fast prototyping, and global shipping with ISO 9001 certified quality.¥0.00¥0.00 -

5-Axis CNC Precision Machined Parts Multi-Material Custom High Accuracy Components

These are high-precision 5-axis CNC machined parts made from aluminum alloy, stainless steel, copper, and other materials. Widely used in machinery, automotive, electronics, and more. Customization is available based on drawings or samples, with excellent surface quality, fast delivery, and quality assurance.¥0.00¥0.00